Rebuild and Repair of a Mori Seiki Model# MS-850 Lathe

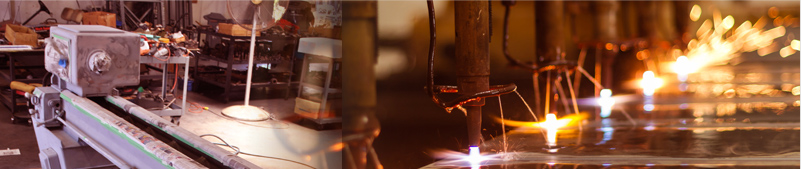

(click on thumbnail to enlarge)

At Dan’s Machine Tool, we can bring non-functioning equipment back to working order for a fraction of new equipment cost. This capability is highlighted with the Mori Seiki MS-850 lathe shown here which was repaired and rebuilt for a customer in the tooling industry. When the lathe arrived at our facility it was in complete disrepair. We disassembled the primary components to assess the level of wear and provide the customer with a preliminary repair estimate.

The spindle, apron, tail stock, and head stock were all completely rebuilt. All spindle bearings were replaced and both x and y axes were aligned. The bed ways were removed, ground, and restored to parallel. The aprons were then scraped to fit the newly repaired bed ways and the cross slides were scraped to fit the aprons. After the compound was scraped to fit the cross slide, all compound and cross slide hardware was replaced with new nuts and screws.

The tail stock was then scraped to align with the spindle and cross slide. Finally, the rack was built up to fit the carriage, resulting in a fully aligned, functioning lathe. In addition, a Newall AP-700 digital 2-axis readout was added for the customer. The finished lathe was primed and painted gray for an attractive and protective finish.

We have extensive experience in the repair and rebuilding of a wide array of machining equipment including older mills and lathes. These machines were built with durable materials and high quality components and can often provide decades of service after refurbishment. For additional details about this lathe repair and refurbishment project, see the table below, or contact us directly.

Rebuild and Repair of a Mori Seiki Model# MS-850 Lathe Highlights

- Project Description

- Rebuild of a Lathe

- Capabilities Applied/Processes

-

- Primary:

Repair

Rebuilding

Head Stock Rebuilding

Rail Grinding

Realignment - Secondary:

Cleaning

Primed and Painted

- Primary:

- Equipment Type

- Mori Seiki Model# MS-850 Lathe

- Material Finish

- Clean

Primer and Painted Gray

- In process testing/inspection performed

- Functionality Tests

- Industry for Use

- Machine Tool

- Standards Met

- Customer Specifications

- Steps

- Completely rebuilt the spindle, Head Stock, Apron, Tailstock and replaced the spindle bearings

Completely realigned the ( X and Y axis)

Bed ways were removed, ground and made parallel

The Apron was scraped to fit the bed way

Cross Slide was scraped to fit Apron

Compound was scraped to fit Cross Slide

Compound and Crossslide Screw and nuts were replaced with new

Tail stock was scraped to align with spindle and cross slide

The rack was built up to fit carriage

- Additional Information

- Installed a Newall AP-700 (2 axis digital readout)

- Project Name

- Rebuild and Repair of a Mori Seiki Model# MS-850 lathe

Print This Page

Print This Page